How the leading-edge use of AI in manufacturing is changing the industry processes.

Unprecedented challenges in the manufacturing sector now get handled with an innovative and exciting approach. Here we are looking at the various AI in manufacturing use cases that manufacturing industries have implemented to increase efficiency.

Manufacturing industries in recent years have expressed a fair deal of interest in AI solutions. There are several reasons why they choose AI to operate their businesses, but use cases of supply management, safety, and security are the ones with the highest demand. AI in manufacturing reduces downtime and ensures high-quality final products. Additionally, manufacturing companies are integrating AI-based analytical tools into their information systems to increase productivity. This article will highlight the popular AI use cases in the manufacturing industry and how it benefits them.

What is AI in manufacturing?

Let us first delve into what AI in manufacturing means. Artificial intelligence in manufacturing refers to using technology to automate complex operations and uncover previously unidentified patterns in manufacturing techniques or workflows. Many businesses have noticed this and begun adopting AI in manufacturing industries to improve processes. According to Markets & Markets, the market for artificial intelligence in manufacturing will reach $16.7 billion by 2026, expanding at a CAGR of 57.2%.

Manufacturers can monitor their facilities in real time using essential Fourth Industrial Revolution (4IR) technologies like machine learning, automation, advanced predictive analytics, and IoT (Internet of Things). This helps in gathering enormous volumes of operational data to:

- Follow important KPIs, such as OEE, production efficiency, etc.

- Predict delivery dates accurately to avoid deadline violations

- Identify probable supply chain disruptions

- Identify and resolve production bottlenecks

- Recognize and address equipment inefficiencies as they arise.

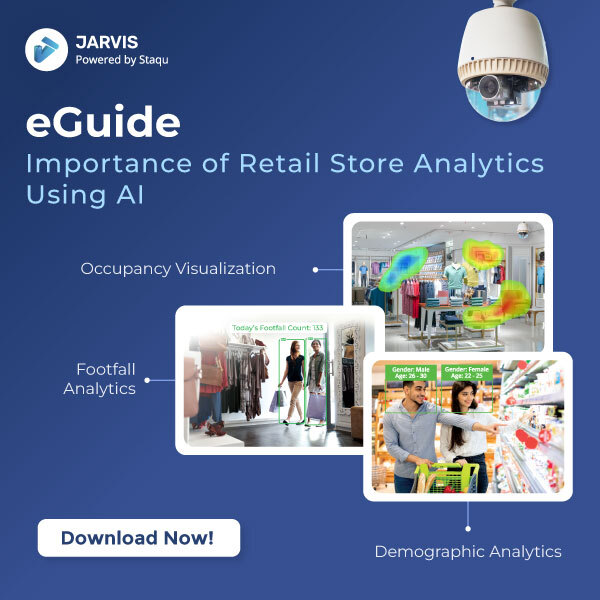

Download eguide

Related Read: Top Use Cases of Automatic Number Plate Recognition(ANPR) Technology of AI-Powered Video Analytics

How is AI used in manufacturing?

Below you will find the best AI use cases to know how AI is used in manufacturing:

Quality Control

Quality Control is one of the best applications of AI in manufacturing. AI-powered defect detection uses computer vision, which uses high-resolution cameras to monitor every step of the production process. Such technology can detect flaws the human eye may miss and initiate automatic corrective action. By doing so, there is a decline in product recalls and waste. In factories, real-time detection of anomalies such as harmful gas emissions, fire, etc., improves worker safety and helps avert workplace risks.

AI in manufacturing sector hence ensures quality control. Artificial intelligence (AI) technologies monitor machine productivity, identify defects, increase output, and cut maintenance expenses. Due to this, most manufacturing companies use AI to automate production operations.

Detecting safety measures

One of the main issues in every manufacturing facility is worker safety. Risky activities, robotic cells, high voltage, and forklift regions must be monitored and kept under check. Companies also need to check their EHS risks, and implementing video analytics solutions for manufacturing processes will help them manage these risks efficiently.

Using Jarvis, Staqu’s video analytics solutions, you can detect personal protective equipment (PPE) such as helmets, safety vests, gloves, etc. Suppose it finds a human in a dangerous place or situation. In that case, it instantly generates a digital output in real-time that may be applied to various desired circumstances.

Supply Chain Management

By evaluating multiple scenarios, AI-enabled solutions can track vehicle behavior in a manufacturing facility. This use case helps manufacturing companies enhance last-mile deliveries and analyze the supply chain’s real-time functioning. Leading manufacturing companies utilize Jarvis’s Automatic Number Plate Recognition (ANPR) feature to keep track of their supply management systems.

Book A Free Demo

AI can give manufacturers more control over their supply networks, from inventory tracking and management to capacity planning. They can set up a real-time, predictive supplier monitoring and evaluation model so that they are alerted as soon as a supplier fails and can assess the severity of the supply chain interruption immediately.

AI Process Automation

Artificial intelligence-powered process mining tools can automatically locate and remove manufacturing process bottlenecks. Manufacturers can compare manufacturing performance across several areas thanks to these technologies. To create better manufacturing processes, they can standardize and streamline workflows.

Automation of processes can also:

- Shortened cycle times

- Increased output

- Increased precision

- Increase workplace security

- Boost productivity and morale among employees

Final Thoughts

Industry leaders have embraced digital transformation in the manufacturing industry for better efficiency and ROI. Artificial intelligence can monitor people, products, and equipment of all kinds. AI solutions like video analytics will continue to record every manufacturing facility with its cycle time, avoid errors, and identify safety and security threats. Jarvis is an innovative approach to artificial intelligence in manufacturing, and we continue to help your business with your daily operations.

Get in touch with us to book a demo today!